kiv puag ncig nyob rau hauv cov khoom siv stator kev lag luam

Nyob rau hauv xyoo tas los no, kev lag luam thoob plaws ntiaj teb tau ua tiav qhov tseem ceeb, uas tau tsav los ntawm kev siv thev naus laus zis uas tau hloov pauv peb lub neej. Ib qho ntawm cov chaw uas tau cuam tshuam loj heev yog cov khoom siv stator kev lag luam. Cov cuab yeej stator tau dhau los ua ib qho kev hloov pauv nrog kev qhia txog cov thev naus laus zis tshiab, ua rau muaj kev txhim kho kev ua haujlwm, kev ua haujlwm thiab kev ua haujlwm zoo.

Cov cuab yeej stator yog ib qho tseem ceeb ntawm ntau lub tshuab xws li cov tshuab hluav taws xob thiab cov tshuab hluav taws xob. Nws yog lub luag haujlwm rau rotating qhov chaw ruaj khov ntawm qhov system, tsim cov electromagnetic teb uas tseem ceeb rau kev ua haujlwm ntawm cov khoom siv no. Kev lig kev cai, cov khoom siv stator tau tso siab rau cov qauv tsim, txwv nws qhov kev ua tau zoo thiab hloov tau.

Txawm li cas los xij, nrog lub advent ntawm technology breakthroughs, lubkhoom siv statorkev lag luam tau dhau qhov kev hloov pauv. Ib qho kev nce qib tseem ceeb tshaj plaws yog kev txhim kho 3D luam ntawv hauv stator manufacturing. Qhov kev siv thev naus laus zis no ua rau muaj kev tsim qauv thiab kev kho kom haum, tso cai rau kev tsim cov khoom siv stator uas ua tau raws li cov kev xav tau tshwj xeeb. Tsis tas li ntawd, 3D luam ntawv txo cov sij hawm tsim khoom thiab cov nqi, ua rau cov khoom siv stator siv tau thiab pheej yig dua li yav dhau los.

Lwm qhov kev ua haujlwm tseem ceeb hauv kev lag luam khoom siv stator yog kev siv cov ntse sensors nrog IoT (Internet of Things). Los ntawm kev sib xyaw cov sensors rau hauv cov khoom siv stator,manufacturerstuaj yeem saib xyuas thiab sau cov ntaub ntawv hauv lub sijhawm ntawm kev ua haujlwm, kub thiab kev co. Cov ntaub ntawv no tso cai rau kev saib xyuas kev kwv yees, kev tshawb pom ntxov ntawm kev ua tsis tiav, thiab txhim kho kev ua haujlwm zoo. Cov peev txheej no tau txhim kho ntxiv los ntawm kev sib koom ua ke ntawm IoT thev naus laus zis, tso cai rau cov chaw taws teeb saib xyuas thiab tswj cov khoom siv stator tsis hais thaj chaw twg.

Tsis tas li ntawd, kev nce qib hauv cov ntaub ntawv tshawb fawb tau pab txhim kho cov khoom siv stator. Kev tsim cov ntaub ntawv tshiab, xws li cov alloys tshwj xeeb thiab cov khoom sib xyaw, tso cai rau cov khoom siv stator kom muaj zog ntau dua, tiv thaiv tshav kub thiab hluav taws xob conductivity. Cov kev nce qib no ua kom lub neej ntev thiab kev ntseeg siab, txo cov nqi tu thiab sijhawm poob.

Zuag qhia tag nrho, kev taw qhia txog kev ua haujlwm thev naus laus zis hauv kev lag luam khoom siv stator tau hloov pauv tag nrho nws cov toj roob hauv pes. Kev siv 3D luam ntawv, kev sib koom ua ke ntawm cov ntse sensors thiab Is Taws Nem ntawm Yam, thiab kev nce qib hauv cov ntaub ntawv tshawb fawb tau noj cov kev ua haujlwm thiab kev ua haujlwm ntawm cov khoom siv stator mus rau qhov siab tshiab. Qhov kev hloov pauv no ua rau txoj hauv kev rau yav tom ntej uas cov cuab yeej stator ua lub luag haujlwm tseem ceeb hauv kev tsim hluav taws xob ruaj khov, kev thauj mus los thiab kev siv lag luam. Raws li kev siv thev naus laus zis txuas ntxiv mus, peb tsuas tuaj yeem tos ntsoov rau kev tsim kho tshiab ntxiv thiab kev tshawb pom ntawm qhov muaj peev xwm tshiab hauv thaj chaw txaus nyiam no.

Feem ntau cov teeb meem hauv kev tsim khoom siv stator

Feem ntau cov teeb meem hauv kev tsim khoom stator tshwm sim los ntawm cov txheej txheem ib txwm muaj nrog cov txheej txheem tsim khoom. Cov txheej txheem no tsis yog siv sijhawm ntev xwb, tab sis kuj siv zog ua haujlwm thiab ua rau tib neeg yuam kev. Kev tsim cov thev naus laus zis qub ntxiv ua rau cov teeb meem no hnyav dua los ntawm kev txwv kev tsim thiab kev ua haujlwm ntawm cov khoom siv stator, thaum kawg cuam tshuam kev ua haujlwm thiab kev ua haujlwm. Yog li ntawd, qhov kev xav tau ntawm kev tsim kho tshiab thiab qib siab tshaj plaws hauv kev lag luam stator khoom tsim tau dhau los ua qhov tseem ceeb.

Cov txheej txheem tsim stator ib txwm xav kom cov neeg ua haujlwm txawj ua haujlwm los ua ke txhua yam khoom. Qhov kev cia siab ntawm kev ua haujlwm ntawm phau ntawv no tsis tsuas yog nce lub sijhawm tsim khoom, tab sis kuj qhia txog kev pheej hmoo ntawm tib neeg kev ua yuam kev. Txhua tus stator yog ib qho cuab yeej uas muaj ntau yam complex uas yuav tsum tau ua tib zoo saib xyuas. Txawm tias qhov yuam kev me me tuaj yeem ua rau tsis muaj txiaj ntsig thiab txo cov khoom zoo. Cov kev cov nyom no tau ua rau muaj kev nyuaj siab ntxiv los ntawm qhov tsis sib xws hauv kev ua haujlwm ntawm tes uas ua rau nws nyuaj rau kev tswj xyuas qhov sib xws hauv cov khoom tsim khoom.

Lwm qhov kev sib tw tseem ceeb nrog cov qauv tsim stator yog cov kev txwv uas tau tsim los ntawm kev tsim cov thev naus laus zis qub. Cov thev naus laus zis no feem ntau txwv kev tsim thiab kev ua haujlwm ntawm cov khoom siv stator, cuam tshuam kev tsim kho tshiab thiab txo kev ua haujlwm tag nrho. Raws li thev naus laus zis txhim kho, qhov kev thov rau cov khoom siv stator muaj txiaj ntsig txuas ntxiv mus ntxiv. Txawm li cas los xij, nrog cov txheej txheem tsim khoom ib txwm muaj, suav nrog cov qauv tsim tshiab thiab kev txhim kho kev ua tau zoo dhau los ua qhov teeb meem tseem ceeb.

Txhawm rau daws cov teeb meem no, cov tuam txhab lag luam tau nce siab siv cov thev naus laus zis xws li cov txheej txheem tsim khoom siv hluav taws xob thiab siv computer-aided tsim (CAD). Cov kev tsim kho tshiab no tau hloov kho cov khoom siv stator los ntawm kev tsim cov khoom lag luam, txhim kho kev sib raug zoo, thiab txhim kho tag nrho cov khoom zoo.

Automated ntau lawm txheej txheem tshem tawm kev cia siab ntawm kev siv tes ua haujlwm, tso cai rau kev tsim khoom sai dua thiab raug dua. Advanced machinery thiab robotics tuaj yeem ua haujlwm ua ke nrog kev ua haujlwm siab, txo qhov kev pheej hmoo ntawm tib neeg kev ua yuam kev. Qhov no tsis tsuas yog txhim kho kev tsim khoom, tab sis kuj ua kom muaj kev sib luag thiab zoo ntawm cov khoom kawg. Cov neeg tsim khoom tam sim no tuaj yeem ua tau raws li cov neeg xav tau ntau dua thiab txo lub sijhawm xa khoom.

Computer-aided design (CAD) plays lub luag haujlwm tseem ceeb hauv kev kov yeej cov kev txwv ntawm kev tsim cov thev naus laus zis qub. Nrog CAD, cov tuam ntxhab tuaj yeem tsim thiab kho cov qauv stator nrog kev hloov pauv ntau dua. Qhov no optimizes kev ua tau zoo thiab kev ua haujlwm ntawm stator, yog li txhim kho tag nrho cov kev ua haujlwm ntawm lub cev. CAD tseem tso cai rau cov tuam txhab simulate thiab txheeb xyuas tus cwj pwm ntawm stator nyob rau hauv kev ua haujlwm sib txawv, kom ntseeg tau tias tus qauv tsim tau raws li qhov xav tau tshwj xeeb.

Tsis tas li ntawd, kev nce qib ntawm cov khoom siv, xws li kev siv lub teeb yuag thiab kev ua haujlwm siab, tau ua cov khoom siv stator tsis tsuas yog siv tau zoo dua, tab sis kuj muaj zog dua thiab tiv taus ib puag ncig. Cov ntaub ntawv no muab kev txhim kho hluav taws xob rwb thaiv tsev, txo qhov poob thiab ua kom tag nrho cov system efficiency.

Kev nce qib hauv Stator Equipment Manufacturing Technology

1.Automation thiab robotics hauv stator khoom tsim

Automation thiab robotics muaj undoubtedly revolutionized manufacturing, thiab stator khoom manufacturing tsis muaj kev zam. Nrog kev nce qib hauvautomation thiab robotics, cov chaw tsim khoom niaj hnub tau ua tiav qhov kev txhim kho tseem ceeb hauv kev tsim khoom, kev ua haujlwm zoo, thiab tag nrho cov khoom zoo.

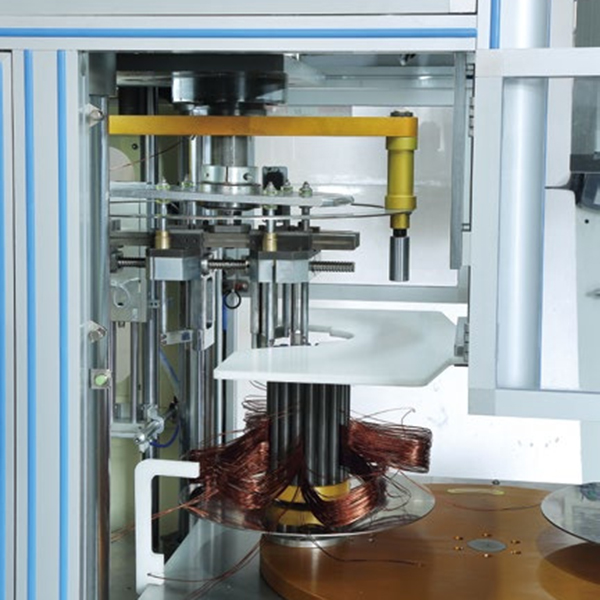

Ib qho ntawm cov chaw tseem ceeb uas automation thiab robotics muaj kev cuam tshuam loj rau kev tsim khoom stator yog cov txheej txheem coil winding. Kev siv cov tshuab winding robotic hloov cov neeg ua haujlwm hauv phau ntawv thiab ua kom cov qauv zoo sib xws. Qhov no ua kom muaj kev sib faib ntawm cov electromagnetic teb nyob rau hauv lub stator. Qhov no tsis yog tsuas yog txhim kho kev ua haujlwm ntawm cov khoom siv stator, tab sis kuj txo qis qhov yuav ua tsis tiav thiab ua rau muaj kev ntseeg siab ntawm cov khoom siv tag nrho.

Lwm qhov kev siv automation thiab robotics hauv stator cov khoom tsim khoom yog nyob rau hauv cov txheej txheem xws li lamination thiab rwb thaiv tsev. Cov dej num no xav tau qhov tseeb thiab qhov tseeb thiab tuaj yeem ua tiav tau zoo dua los ntawm kev siv automation. Cov neeg hlau muaj peev xwm deftly lis cov stator Cheebtsam thiab siv cov txheej txheem tsim nyog thiab rwb thaiv tsev yam tsis muaj tib neeg yuam kev. Qhov no tsis tsuas yog txhim kho kev tswj xyuas zoo ntawm cov khoom siv stator, tab sis kuj txo cov kev cia siab ntawm kev ua haujlwm, yog li txo cov nqi zog.

Kev txais yuav ntawm automation thiab robotics hauv stator cov cuab yeej tsim khoom kuj tau coj cov txiaj ntsig tseem ceeb rau kev lag luam tag nrho. Ua ntej, nws ua kom muaj txiaj ntsig tag nrho thiab kev tsim khoom nrawm. Cov neeg hlau tuaj yeem ua haujlwm tsis tu ncua yam tsis tau so, tso cai rau cov txheej txheem tsim khoom tau zoo dua. Thib ob, automation tuaj yeem ua cov haujlwm raug thiab rov ua haujlwm tsis tu ncua, ua kom muaj qhov raug siab thiab txo qhov yuam kev. Qhov no thaum kawg txhim kho cov khoom zoo.

Tsis tas li ntawd, kev sib koom ua ke ntawm automation thiab robotics nyob rau hauv stator cov cuab yeej tsim khoom tuaj yeem ua rau kev txuag nqi. Kev nqis peev thawj zaug hauv robotics thiab automation systems tuaj yeem loj, tab sis nyob rau lub sijhawm ntev, nws tuaj yeem txhais ua cov nqi qis zog. Los ntawm kev txo qis kev xav tau ntawm kev siv tes ua haujlwm thiab kev ua kom zoo tshaj plaws, cov tuam txhab tuaj yeem ua tiav cov txiaj ntsig tseem ceeb thiab txhim kho lawv cov kev sib tw kom zoo dua.

Raws li tsab ntawv ceeb toom los ntawm Marketsand Markets, kev lag luam thoob ntiaj teb kev lag luam neeg hlau xav tias yuav muaj nqis txog US $ 61.3 nphom los ntawm 2023. Qhov kev kwv yees no qhia ntxiv txog qhov tseem ceeb zuj zus thiab kev siv automation thiab robotics hauv stator khoom tsim. Raws li kev siv thev naus laus zis txuas ntxiv mus, peb tuaj yeem cia siab tias yuav muaj kev nce qib ntau dua hauv automation thiab robotics hauv daim teb no.

Automation thiab robotics tau coj kev nce qib tseem ceeb hauv kev tsim khoom siv stator. Los ntawm kev siv neeg hlau winders thiab automation nyob rau hauv cov txheej txheem xws li lamination thiab rwb thaiv tsev, manufacturers tuaj yeem txhim kho precision, nce ceev, txhim khu kev tswj zoo thiab txo nqi zog. Raws li kev tsim khoom thoob ntiaj teb txuas ntxiv tuav automation thiab robotics, stator cov khoom lag luam yuav tsum ua haujlwm los siv cov thev naus laus zis kom nyob twj ywm kev sib tw thiab ua tau raws li kev xav tau ntawm kev lag luam loj hlob.

2. Cov khoom siv qib siab hauv Stator Equipment Manufacturing

Cov ntaub ntawv qib siab tau hloov pauv lub ntiaj teb ntawm cov khoom siv stator tsim, hloov pauv txoj hauv kev tsim cov khoom hluav taws xob tseem ceeb no. Kev sib koom ua ke ntawm cov ntaub ntawv xws li cov polymers siab heev, cov khoom sib xyaw thiab cov laminates ua tau zoo muaj kev cuam tshuam loj heev rau kev ua haujlwm ntev, thermal kuj thiab txhua yam muaj zog ntawm cov khoom siv stator.

Ib qho txiaj ntsig tseem ceeb tshaj plaws ntawm kev siv cov khoom siv qib siab hauv kev tsim cov khoom siv stator yog ua kom muaj txiaj ntsig tag nrho ntawm cov khoom no. Nrog kev taw qhia ntawm cov khoom hnyav thiab cov ntaub ntawv permeable heev, kev ua haujlwm ntawm cov khoom siv stator tau txhim kho zoo heev. Tsis tsuas yog ua cov ntaub ntawv no tso cai rau kev hloov hluav taws xob ntau dua, tab sis lawv kuj pab txo qis hauv qhov system.

Nyob rau hauv xyoo tas los no, kev nce qib hauv nanotechnology tau txhawb kev txhim kho cov ntaub ntawv nanocomposite rau stator windings. Cov nanocomposites no muaj cov hluav taws xob zoo heev thiab thermal conductivity, uas ua rau muaj zog ntau zog thiab txo qhov poob. Raws li lub zog ceev nce, cov khoom siv stator ua ntau dua thiab muaj txiaj ntsig, ua rau cov nqi txuag rau cov tuam txhab thiab txhim kho kev ua haujlwm.

Kev koom ua ke ntawm cov khoom siv siab heev hauv kev tsim khoom stator kuj tseem ua rau cov tuam txhab tsim cov khoom siv ruaj khov thiab txhim khu kev qha. Piv txwv li, cov laminates ua tau zoo muaj kev hnav zoo heev, ua kom cov khoom siv stator tuaj yeem tiv taus cov xwm txheej hnyav uas nws ua haujlwm tsis tu ncua.

Tsis tas li ntawd, cov khoom siv qib siab no ua lub luag haujlwm tseem ceeb hauv kev txhim kho kev nyab xeeb ntawm cov khoom siv stator. Kev siv cov khoom siv polymers siab heev thiab cov khoom sib xyaw ua ke pab txhim kho cov khoom siv rwb thaiv tsev, tiv thaiv kom tsis txhob tawg thiab txo kev pheej hmoo ntawm kev raug mob.

Cov tuam txhab tshwj xeeb hauv kev tsim cov khoom siv stator yog embracing advanced cov ntaub ntawv, paub lawv lub peev xwm rau innovation thiab efficiency. Los ntawm kev koom nrog cov ntaub ntawv no rau hauv cov txheej txheem tsim khoom, lawv muaj peev xwm tsim cov khoom siv stator uas tsis yog tsuas yog siv tau zoo xwb tab sis kuj ua tau raws li qhov xav tau ntawm kev lag luam niaj hnub no.

Kev koom ua ke ntawm cov khoom siv siab heev hauv kev tsim khoom stator tau hloov pauv lub teb. Cov ntaub ntawv no, xws li cov polymers siab heev, cov khoom sib xyaw thiab cov laminates ua haujlwm siab, muaj ntau dua durability, kub tsis kam thiab mechanical zog. Tsis tas li ntawd, kev siv lub teeb yuag, cov ntaub ntawv permeable heev ua rau muaj kev ua tau zoo tag nrho. Raws li nanotechnology txuas ntxiv mus, cov tuam txhab tam sim no tuaj yeem tsim cov nanocomposites rau stator windings, ntxiv zog kom ceev thiab txo qhov poob. Raws li qhov tshwm sim, cov khoom siv stator tau dhau los ua kev sib cog lus ntau dua, ua haujlwm tau zoo thiab raug nqi, muab ntau yam txiaj ntsig rau cov tuam txhab thiab kev lag luam. Los ntawm kev siv cov khoom siv siab heev, cov tuam txhab hauv stator cov cuab yeej tsim khoom lag luam tau npaj rau kev loj hlob ntxiv thiab kev tsim kho tshiab.

3.Virtual Design & Prototyping: Lub Game Changer rau Stator Equipment Development

Virtual tsim thiab prototyping thev naus laus zis tau hloov kho cov txheej txheem tsim khoom rau cov khoom siv stator. Yav dhau los, cov neeg tsim khoom yuav tsum cia siab rau lub cev qauv los sim lawv cov qauv tsim, uas yog siv sijhawm ntev thiab kim. Txawm li cas los xij, nrog rau qhov tshwm sim ntawm virtual simulation thiab digital prototyping, cov tuam txhab tam sim no tuaj yeem txhim kho cov qauv tsim, tshawb xyuas qhov tsis xws luag thiab txhim kho cov khoom ua haujlwm ua ntej tsim cov cuab yeej.

Virtual tsim thiab prototyping software tso cai rau cov tuam txhab tsim digital replicas ntawm cov cuab yeej stator, ua tiav nrog cov ncauj lus kom ntxaws thiab cov khoom siv. Cov qauv digital no tuaj yeem hloov kho thiab txheeb xyuas los txheeb xyuas cov teeb meem uas muaj peev xwm lossis thaj chaw rau kev txhim kho. Los ntawm kev ua virtual simulation, cov tuam txhab tuaj yeem sim cov kev ua tau zoo thiab kev ntseeg siab ntawm cov cuab yeej stator nyob rau hauv ntau yam kev ua haujlwm kom paub txog kev txiav txim siab tsim.

Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm kev tsim virtual thiab prototyping yog lub peev xwm los txheeb xyuas qhov tsis xws luag thaum ntxov hauv txoj kev loj hlob. Los ntawm kev simulating kev ua tau zoo ntawm cov khoom siv stator, cov tuam ntxhab tuaj yeem txheeb xyuas cov ntsiab lus tsis muaj zog lossis cov ntsiab lus kev ntxhov siab uas tuaj yeem ua rau tsis ua haujlwm lossis tsis zoo. Qhov no tso cai rau lawv los tsim kev hloov kho lossis xaiv lwm cov ntaub ntawv los txhim kho tag nrho cov khoom zoo thiab kav ntev.

Tsis tas li ntawd, virtual tsim thiab prototyping thev naus laus zis tso cai rau cov tuam txhab tsim cov qauv tsim los txhim kho kev ua haujlwm thiab kev ua haujlwm zoo. Los ntawm simulating cov cuab yeej hauv ib puag ncig virtual, cov tuam txhab lag luam tuaj yeem soj ntsuam cov kev tsim qauv sib txawv thiab txiav txim siab qhov kev teeb tsa zoo tshaj plaws. Qhov no pab txo tus naj npawb ntawm cov qauv siv lub cev xav tau thiab txuag lub sijhawm tseem ceeb thiab tus nqi hauv txoj kev txhim kho.

Ntxiv nrog rau kev tsim kho kom zoo, kev tsim virtual thiab kev tsim qauv kuj tuaj yeem pab txhim kho cov khoom lag luam. Los ntawm kev simulating tus cwj pwm ntawm cov cuab yeej stator nyob rau hauv cov kev ua haujlwm sib txawv, cov tuam txhab tuaj yeem txheeb xyuas cov kev ua haujlwm tsis zoo thiab ua kom muaj kev hloov kho tsim nyog los txhim kho cov khoom lag luam thiab kev ua haujlwm. Qhov no ua kom ntseeg tau tias cov khoom kawg ua tau raws li lossis tshaj qhov yuav tsum tau ua ntawm kev ua haujlwm.

Tsis tas li ntawd, virtual tsim thiab prototyping thev naus laus zis ua rau cov tuam txhab lag luam sib txuas lus zoo rau lawv cov tswv yim tsim rau cov neeg muaj feem xws li cov neeg siv khoom, cov chaw muag khoom, thiab cov koom haum tswj hwm. Cov qauv digital nthuav dav ua kom pom qhov pom tseeb thiab ua kom pom tias lub tshuab stator ua haujlwm li cas hauv qhov xwm txheej tiag tiag. Qhov no pab kom tau txais cov neeg koom nrog yuav khoom thiab ua kom cov khoom kawg ua tau raws li lawv qhov kev cia siab.

Virtual tsim thiab prototyping coj kev nce qib tseem ceeb rau cov txheej txheem tsim khoom rau cov khoom siv stator. Lub peev xwm los txhim kho cov qauv tsim, tshawb xyuas qhov tsis xws luag thiab txhim kho cov khoom lag luam ua ntej kev tsim khoom tiag tiag txuag lub sijhawm thiab cov nqi tsim khoom. Virtual tsim thiab prototyping thev naus laus zis tau dhau los ua cov cuab yeej tseem ceeb hauv kev lag luam, tso cai rau cov tuam txhab tsim cov khoom siv stator zoo uas ua tau raws li cov neeg siv khoom xav tau.

4.Maximizing Efficiency: Yuav ua li cas Sensor Tech Impacts Stator Mfg

Sensor technology nyob rau hauv stator khoom manufacturing Sensor technology plays lub luag hauj lwm tseem ceeb nyob rau hauv stator khoom manufacturing, enabling real-time xyuas, fault detection thiab kwv yees txij nkawm.

Los ntawm embedding sensors nyob rau hauv lub stator windings thiab lwm yam khoom, manufacturers yuav tsis tu ncua saib xyuas qhov tseem ceeb tsis xws li kub, vibration thiab rwb thaiv tsev mob. Cov sensors no muab kev nkag siab zoo rau stator kev noj qab haus huv thiab kev ua haujlwm, ua kom muaj kev saib xyuas zoo thiab txo qis kev ua tsis tiav.

Hauv ntiaj teb nostator khoom tsim khoom, tswj kev ua haujlwm kom zoo thiab tiv thaiv kev ua tsis tiav yog qhov tseem ceeb. Stators yog cov khoom tseem ceeb hauv ntau qhov kev lag luam, nrog rau kev tsim hluav taws xob, kev siv tshuab thiab kev thauj mus los. Cov tshuab no feem ntau ua haujlwm nyob rau hauv ib puag ncig hnyav thiab raug kub siab, kev vibrations thiab hluav taws xob loads. Stator tsis ua haujlwm tuaj yeem ua rau raug nqi poob qis, kev tsim khoom ploj thiab muaj kev nyab xeeb.

Cov txheej txheem kev tu ib txwm cia siab rau kev tshuaj xyuas tsis tu ncua thiab kho qhov rov ua haujlwm. Txawm li cas los xij, txoj hauv kev no feem ntau tsis muaj txiaj ntsig thiab tsis muaj txiaj ntsig. Nws tsis muab cov ntaub ntawv ntawm lub sijhawm tiag tiag txog kev noj qab haus huv ntawm stator, ua rau nws nyuaj rau txheeb xyuas cov teeb meem uas yuav tshwm sim ua ntej lawv nce ntxiv. Qhov no yog qhov chaw sensor technology los ua si.

Los ntawm embedding sensors thoob plaws hauv lub stator thiab txuas lawv mus rau lub tshuab uas sau thiab txheeb xyuas cov ntaub ntawv, manufacturers tuaj yeem tau txais daim duab tiav ntawm tus mob ntawm stator. Piv txwv li, cov ntsuas kub ntsuas tuaj yeem saib xyuas qhov kub thiab ntsuas qhov ntsuas kub tsis zoo, qhia tias muaj peev xwm cuam tshuam kev puas tsuaj los yog qhov ua kom txias tsis ua haujlwm. Vibration sensors tuaj yeem ntes cov kev co ntau dhau, uas tuaj yeem yog ib qho kev qhia ntawm misalignment, bearing coj los yog teeb meem ntawm cov qauv. Rwb thaiv tsev mob sensors saib xyuas kev noj qab haus huv ntawm cov rwb thaiv tsev, ceeb toom cov tuam txhab ntawm qhov ua tsis tiav lossis kev puas tsuaj.

Nrog lub peev xwm saib xyuas lub sijhawm tiag tiag, cov tuam txhab lag luam tuaj yeem tshawb pom cov cim ceeb toom ntxov ntawm cov teeb meem muaj peev xwm, tso cai rau kev saib xyuas raws sijhawm. Los ntawm kev daws teeb meem tam sim ntawd, cov tuam txhab tsim khoom tuaj yeem tiv thaiv qhov ua tsis tau tiav, txo qis sijhawm thiab txuas ntxiv lub neej kev pabcuam tag nrho ntawm lawv cov khoom siv stator. Tsis tas li ntawd, cov ntaub ntawv sau los ntawm cov sensors tuaj yeem siv los txhim kho cov phiaj xwm kev saib xyuas, ua kom muaj txiaj ntsig zoo thiab faib cov peev txheej.

Tsis tas li ntawd, cov cuab yeej siv hluav taws xob tso cai rau kev saib xyuas kev kwv yees, cia siab tias yuav ua tsis tiav thiab ua cov kauj ruam tiv thaiv kom tiv thaiv lawv. Los ntawm kev txheeb xyuas cov ntaub ntawv sau los ntawm cov sensors, cov tuam txhab lag luam tuaj yeem txheeb xyuas cov qauv thiab cov qauv uas qhia txog cov teeb meem yav tom ntej. Nrog rau qhov kev paub no, cov tuam ntxhab tuaj yeem npaj ua ntej, xaj cov khoom tsim nyog hloov pauv, thiab teem caij saib xyuas cov haujlwm thaum lub sijhawm teem sijhawm.

Cov cuab yeej siv hluav taws xob tau hloov pauv cov khoom siv stator tsim los ntawm kev muab kev saib xyuas lub sijhawm tiag tiag, kuaj pom qhov tsis raug thiab kev kwv yees kev tu lub peev xwm. Los ntawm tsis tu ncua saib xyuas qhov tseem ceeb xws li qhov kub thiab txias, kev vibration thiab rwb thaiv tsev, sensors embedded nyob rau hauv stator tuaj yeem muab kev nkag siab zoo rau nws txoj kev noj qab haus huv thiab kev ua haujlwm. Qhov no ua rau cov tuam txhab lag luam coj kev ntsuas kev saib xyuas zoo, txo qis kev ua tsis tiav thiab txhim kho cov khoom siv tag nrho. Nrog rau kev siv thev naus laus zis, stator cov cuab yeej tsim khoom tau nkag mus rau lub sijhawm tshiab ntawm kev ua haujlwm, tsim khoom thiab kev ntseeg tau.

Xaus

Kev siv thev naus laus zis hauv kev tsim khoom siv stator hloov pauv kev lag luam. Automation thiab robotics nce precision thiab efficiency, thaum cov ntaub ntawv siab heev txhim khu durability thiab kev ua tau zoo. Virtual tsim thiab prototyping tau hloov pauv cov txheej txheem kev tsim khoom, thaum lub tshuab sensor ua rau lub sijhawm saib xyuas thiab kwv yees saib xyuas. Kev siv cov kev nce qib no tsis yog tsuas yog txhim kho qhov zoo thiab kev ntseeg siab ntawm cov cuab yeej stator tab sis kuj ua rau cov tuam txhab ua kom tau raws li cov kev hloov pauv ntawm ntau yam kev lag luam. Los ntawm kev tshawb fawb thiab kev txhim kho txuas ntxiv, cov khoom siv stator tsim muaj peev xwm ntau dua rau kev tsim kho tshiab rau yav tom ntej, yog li tsav kev nce qib hauv lub zog tauj dua tshiab, kev thauj mus los thiab lwm yam haujlwm.

Guangdong Zongqi Automation Co., Ltd.feem ntau tsim cov khoom siv lub cev muaj zog, kev sib koom ua ke R & D, kev tsim khoom, kev muag khoom thiab kev muag khoom tom qab muag. Zongqi cov neeg tau koom nrog kev siv tshuab hluav taws xob automation manufacturing tshuab tau ntau xyoo, thiab muaj kev nkag siab tob txog kev siv lub cev muaj feem xyuam nrog kev tsim khoom siv tshuab, thiab muaj kev tshaj lij thiab kev nplua nuj.

Peb lub tuam txhabcov khoomthiab cov kab ntau lawm yog siv rau cov khoom siv hauv tsev, kev lag luam, tsheb, kev tsheb ciav hlau ceev, aerospace thiab lwm yam tsav tsheb dav dav. Thiab cov thev naus laus zis tseem nyob hauv txoj haujlwm ua.Thiab peb tau cog lus los muab cov neeg siv khoom nrog txhua qhov kev daws teeb meem ntawm AC induction lub cev muaj zog thiab DC lub cev muaj zog's ua.

Xav tias dawb rautiv tauj us thaum twg los tau! Peb nyob ntawm no los pab thiab xav hnov los ntawm koj.

Chaw nyob : Chav 102, Thaiv 10, Tianfulai International Industrial City Phase II, Ronggui Street, Shunde District, Foshan City, Guangdong Province

Whatsapp/ Xov tooj:8613580346954

Email:zongqiauto@163.com

Post lub sij hawm: Oct-19-2023