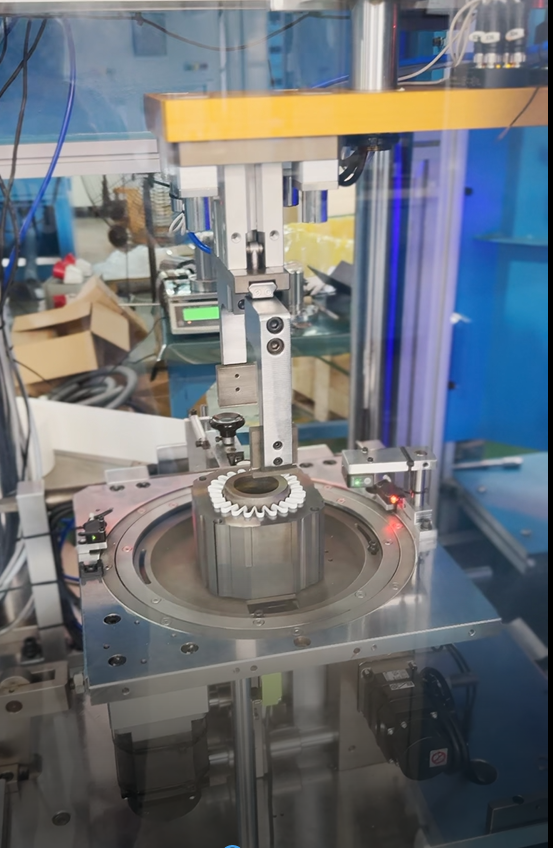

Daim ntawv ntxig tshuab yog cov khoom siv tseem ceeb hauv cov txheej txheem tsim hluav taws xob, feem ntau yog siv los ntxig cov ntawv insulating rau hauv stator slots ntawm lub tshuab hluav taws xob. Cov kauj ruam no yog qhov tseem ceeb rau kev ua haujlwm thiab kev nyab xeeb ntawm lub tshuab hluav taws xob, vim tias nws cuam tshuam ncaj qha rau cov nyhuv rwb thaiv tsev thiab kev ua haujlwm ntawm cov motors. Los ntawm automating cov txheej txheem no, daim ntawv inserting tshuab ho txhim khu kev ua tau zoo thiab raug ntawm lub cev muaj zog ntau lawm.

Nta ntawm Zongqi Automation's Paper Inserting Tshuab

High Precision:Zongqi Automation daim ntawv ntxig tshuab siv cov kev tswj xyuas qib siab thiab cov qauv siv tshuab kom paub meej tias cov ntawv insulating raug muab tso rau hauv stator slots, ua tau raws li qhov yuav tsum tau ua ntawm lub cev muaj zog.

Kev ua haujlwm siab:Daim ntawv inserting tshuab boasts high-speed, nruam kev ua hauj lwm muaj peev xwm, ho boosting efficiency ntawm lub cev muaj zog ntau lawm. Tsis tas li ntawd, nws tuaj yeem ua ke nrog lwm cov khoom siv automated (xws li tshuab winding, shaping machine, thiab lwm yam) los tsim cov kab ntau lawm.

Kev ua haujlwm yooj yim:Zongqi Automation daim ntawv ntxig tshuab yog tsim los nrog cov neeg siv-phooj ywg-tshuab interface, tso cai rau cov tswv lag luam yooj yim pib, nres, thiab teeb tsa cov khoom siv. Tsis tas li ntawd, lub tshuab tau nruab nrog cov lus ceeb toom txhaum cai thiab kev kuaj mob ua haujlwm, ua kom yooj yim rau cov neeg ua haujlwm saib xyuas kom sai thiab daws teeb meem.

Kev ruaj ntseg zoo heev:Daim ntawv ntxig tshuab yog tsim los ntawm cov khoom siv zoo thiab cov khoom siv, ua kom muaj kev ruaj ntseg zoo thiab ruaj khov. Nws tswj kev ua haujlwm zoo ib yam ntawm cov khoom siv hauv lub sijhawm ntev, kev siv zog ua haujlwm siab.

Daim ntawv thov ntawm daim ntawv ntxig tshuab hauv Automated Production Lines

Nyob rau hauv Zongqi Automation's automated motor ntau lawm kab, daim ntawv inserting tshuab feem ntau yog siv nrog rau lwm yam automated khoom los ua ib tug ua tiav cov kab ntau lawm. Cov kab ntau lawm no cia li ua tiav cov txheej txheem xws li lub cev muaj zog winding, ntawv ntxig, shaping, thiab xaim khi, ua kom lub cev muaj zog ntau lawm thiab cov khoom zoo.

Txoj haujlwm thiab lub luag haujlwm ntawm daim ntawv ntxig tshuab hauv cov kab ntau lawm yog qhov tseem ceeb. Nws yog positioned tom qab lub tshuab winding, lub luag hauj lwm rau inserting insulating ntawv rau hauv stator slots uas twb tau raug mob. Thaum cov kauj ruam no ua tiav, tus stator tuaj yeem mus rau theem tom ntej ntawm winding thiab xaim embedding. Kev ua haujlwm tsis siv neeg ntawm daim ntawv ntxig tshuab tsis tsuas yog txhim kho kev tsim khoom, tab sis kuj txo cov kev ua yuam kev thiab kev nyab xeeb kev nyab xeeb cuam tshuam nrog kev ua haujlwm ntawm phau ntawv.

Post lub sij hawm: Nov-11-2024